Call : View Number

PARAS STEEL CENTER

GST : 23AHKPJ4235B1ZV

GST : 23AHKPJ4235B1ZV

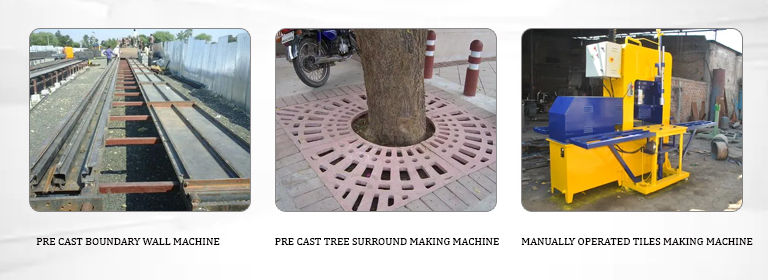

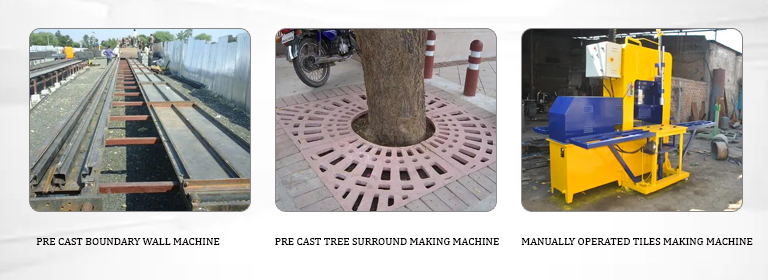

Presenting a comprehensive range of products like Rubber Mould, PVC Mould, Interlock Paver Machine, Power Pack Machine, Pan Mixer Machine, etc.

- New Arrivals

- Featured

Advanced technology along with latest machines and tools has helped Paras Steel Center to deliver machines and equipment as per the clientsâ needs and requirements. This has assisted us in attaining maximum satisfaction of the clients and thus, maintaining a cordial relationship with them. Since 1993, we are engaged in offering highly precision range of machines, which are manufactured with the use of high grade raw material that are sourced from reliable vendors in the country. We are an eminent manufacturer and supplier offering a comprehensive range of products like Rubber Mould, PVC Mould, Interlock Paver Machine, Power Pack Machine, Pan Mixer Machine, and many more.

We have achieved expertise in manufacturing advanced machines that are used by various engineering industries for many purposes. Our team of experts include technical designers, engineers, quality inspectors and other related workforce, who are having complete knowledge about the related industry. All our professionals are experts in their respective domains and can efficiently manage the team with high spirits and motivating force. The new entrants are also trained about the various processes on the usage and operating patterns of the machines, in order to avoid any delays in the working process.

Product Range

Paras Steel Centre is the renowned organization providing the Green Solutions for Building Construction located at Indore City of Madhya Pradesh State. Paras Steel Centre Is the Indiaâs one of the top leading manufacturer & supplier of:

|

|

|

After Sales Service

We offer an excellent on time & satisfactory services to our valuable customers to enable him for smooth running of their plant & make a good profit.

We send our service engineer as soon as machine reached to the customer's site. Not only our engineers do Erection & Commissioning of plat but also give training to your personals to enable them to run the plant smoothly. Necessary Spars parts are always available in our store.

Quality Control

Paras Steel Center, Ball Mill Mixer Machine Manufacturer and Ceramic Ball Mill Machine Supplier has a well maintained in-house quality testing unit, which helps us in delivering quality products like Ball Mill Mixer Machine etc to the customers. Our products are duly manufactured and tested at par with international quality standards. We have appointed a team of quality analysts, who have vast knowledge and experience in this particular field. They carefully monitor each stage of the production process, starting from procuring the raw material till the final dispatch of the consignments. Our products are put through stringent testing to confirm their quality and durability. They are tested on the basis of following parameters:

- Functionality

- Dimensions

- Corrosion resistance

- Abrasion resistance

- Performance

- Construction

Robust Infrastructure

Our Company possesses a state-of-the-art infrastructure, which is equipped with latest machines and technology. Our sturdy manufacturing unit is capable enough to produce the range of high performance products on a very large scale. The manufacturing process involves utilization of most sophisticated tools that are installed at our manufacturing facility. This helps in the smooth production of the products. Our company invests a large amount on the improvement and up gradation of machines based on international technology. Besides, our dedicated and qualified team of engineers & technocrats also contribute tremendously to the smooth functioning of our organization.

Back to top

|

|

|

|

PARAS STEEL CENTER

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry